QLIMS Case Study: Comvita

In this LIMS case study, we explore how Comvita tackled the challenges of rapid growth and ever-evolving regulations. Discover how QLIMS revolutionized their processes, making data-driven decision-making effortless and boosting productivity by 20%.

About Comvita

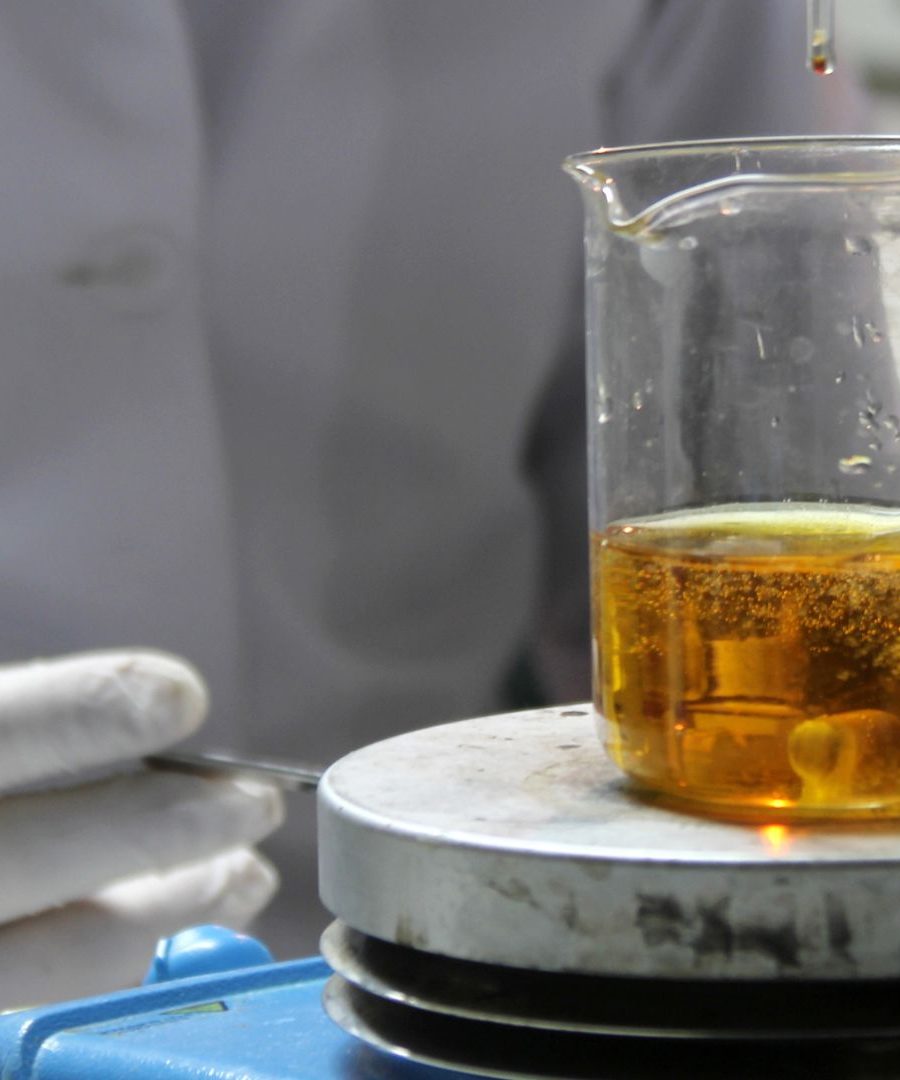

Comvita is a natural health products company primarily focused on bee-based products. Since its founding over 40 years ago, the company has maintained a strong emphasis on science and research, focusing on natural products with proven benefits such as Manuka honey, Propolis, and Olive Leaf Extract.

With over 40,000 hives in New Zealand and an 800,000-tree olive farm in Australia, they control their supply chain from raw material source to the retail shelf, setting a high standard for traceability. The company has expanded its reach to global markets, including China, Asia, the USA, and the UK—each with its own distinct regulations and governance processes. Comvita has structured its operations into two critical teams: the Analytical team and the Quality Control (QC) team.

The Challenges

Facing rapid growth and increasing data demands, Comvita’s laboratory and QC teams were hindered by manual processes, relying heavily on Excel spreadsheets and Word documents. The Laboratory Manager explained: "For us, the driver (for change) was simple: scale."

With new MPI (Ministry for Primary Industries) regulatory requirements for Manuka honey, adopting a new solution became imperative. He noted: "The business has gone through a very fast growth curve, meaning the volume of data entry and the number of tests required became so large that it was no longer sustainable."

| The Solution Comvita began by reviewing business requirements and evaluating software solutions under the direction of a Project Manager. The ability to demonstrate end-to-end traceability of all components was the key factor. The cloud-hosted QLIMS system implemented includes: - Worklist Module - CAPA Module (Corrective and Preventive Action) - Sample Splitting and Collation Module - QLIMS Bridge for instrument integration. - A Customized Quality Control Module specifically designed for Comvita. |

The Results

Comvita's greatest success since implementing QLIMS has been the speed and efficiency of decision-making thanks to data availability. Information from laboratory instruments is entered directly into the database and pushed to BI (Business Intelligence) reports.

The Laboratory Manager stated: "The biggest improvement we’ve seen is in productivity. We believe QLIMS has helped save 20% of our lab technicians' time."

"We also connected QLIMS to our ERP system via the cloud, enabling BI dashboards. This means people can slice and dice data as needed to make decisions in real-time—you just can't do that if the data is sitting in a spreadsheet."

For further support, please contact:

| COE team Email: info@transmed.com.vn Hotline: 0949 934 595 |